Join us this March

For our industry-leading Equipment Reliability-Focused Training

Gain a solid foundation in mechanical seal operation and discover practical insights into root-cause analysis and pump failure modes. This course includes straightforward troubleshooting techniques you can implement immediately.

Led by internationally renowned instructor Chris Dean, this hands-on program combines real-world solutions to boost reliability, minimize failures, and optimize plant performance. 2026 marks the final year Chris will deliver this training. Don’t miss your chance to learn from one of the best.

Go to Registration

Who Should Attend?

This course is ideal for:

- Maintenance personnel • Engineers • Plant operators • Purchasing teams

Or anyone involved in rotating equipment reliability or mechanical seal maintenance. Whether you’re new to the field or a seasoned professional, you’ll leave this training with valuable insights and actionable skills.

Each session features practical guidance, demonstrations, and troubleshooting techniques that participants can apply immediately in their facilities.

Key Topics Covered

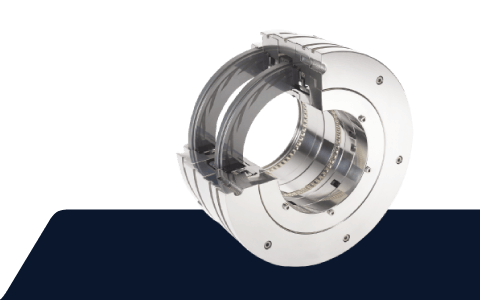

What is a mechanical seal?

- How seals work

- What is good seal life and am I getting it?

- Why use mechanical seals?

- Seal types and configurations

- Rotary v Stationary designs

- Hydraulic balanced and unbalanced seals

- Single / Dual seals

Dual Seals and Support Systems

- Why we use dual seals

- Protecting the fuse in your system

- The difference between barrier and buffer systems, and their application

- Thermosyphon and forced circulation fluid principles

- Internal seal pumping scroll benefits

Centrifugal Pumps: What is a Pump?

- How pump design affects seal and bearing life

- Alignment and its effect on reliability

- Shaft deflection

- Understanding pump curves

- Relationship between head and pressure

- The consequences of using an over-sized pump

- How to troubleshoot pumps without curves

- Cavitation: types, causes, symptoms and cures

- Seal Chamber vs. Stuffing Box design

- Piping systems and their effects on equipment reliability

- Affinity laws – what are they?

What’s Included

Your registration includes everything needed for a seamless, comfortable, and productive experience:

- Training material presented

- Certificate listing all completed training modules

- Breakfast/Lunch

Instructor:

Chris Dean

Chris Dean, AESSEAL Group Technical Training Officer, brings over 48 years of mechanical engineering and global training experience. Known for his engaging, relaxed, and practical approach, Chris ensures that every attendee leaves with deeper knowledge and practical tools to apply immediately in their role.